A company giving love and being loved with trust

HL D&I Halla, a Superior and Solid Global Company

HL D&I Halla’s Safety & Health Management

HL D&I Halla strives to thoroughly implement safety and

health management at all workplaces based on a spirit of respect

for human beings. It has acquired the OHSAS 18001 certification,

is equipped with a global safety and health management system,

and shares its safety and health policy with all employees and

partners. In addition to the company-wide “All-Site Disaster

Prevention” campaign, HL D&I Halla operates safety

campaigns in which the top management participates. We are

striving to improve disaster prevention and safety management

capabilities by operating construction safety experience training

grounds and prior work permits for hazardous work, and running

a joint management consultative group.

By awarding excellent joint safety management and holding

Safety Kick-Off Meetings, the company is inducing and

supporting autonomous safety management and continuously

solving problems with safety check consulting by a specialized outside agency

Left : Declaration ceremony for no disasters for 100 days

Left : Declaration ceremony for no disasters for 100 days

Safety manager workshops twice a year in all construction sites. Safety manager workshops educate safety managers essential information safety managers must be aware of such as enacted or revised laws and disaster case studies. Through the workshops, safety managers discuss problems of on-site safety management, seek solutions and renew their commitment to taking them into action, thereby enhancing work capabilities of safety managers. Safety manager group meetings by regions On-site groups are organized by regions and they hold monthly meetings to facilitate communication among safety managers and benchmark case studies of good safety management by sites.

HL D&I Halla. conducts inspections on the on-site implementation status of OHSAS 18001 requirements, safety management plan, as well as hazard and risk prevention plan more than once a year and offers guidance and education to prevent accidents and establish and implement health and safety management system.

HL D&I Halla. selects key safety management target points on a monthly basis and offers intensive management on them by sites and reports performance results to the headquarters for feedback

The PTW system refers to a system in which accident-prone or hazardous/dangerous types of construction are selected in advance and supervisors from subcontractors for those projects are required to establish safety plans and receive permission from the project manager and safety manager prior to commencement of work. This system enhances safety awareness of supervisors from subcontractors and encourages their voluntary participation.

Quality Management Our corporate philosophy requires us to never compromise on quality and to conduct thorough quality control at every construction site. We obtained the ISO 9001 quality management certificate and have secured a systematic approach to quality management. Our quality management directives are paramount in every aspect of operations inside and outside the company. Top management and representatives from suppliers have shop-floor quality campaigns. On-site quality inspections and monthly quality competitions are also conducted to provide customers with the highest quality structures. Our quality management activities will continue to help strengthen brand recognition and raise customer satisfaction and trust.

Safety and quality campaign (2020)

Safety and quality campaign (2020)

Customer

requirements

Continuous

improvement

Customer

satisfaction

Measurement

analysis improvement

· internal evaluation

· autonomous

inspection

· NCR / CAR

· quality analysis

Operational

accountability

· quality policy

and objectives

· duties divisions

· site overview

Product

realization

· design review

· official’s approval

· contract document

· correction

management

Resource

management

· quality

management

resources

· quality education

HL D&I Halla. conducts inspections on the on-site implementation status of ISO 9001 requirements, quality control plans, and testing plans, provides guidance and education more than once a year and offers high-quality products through ongoing improvements of inspection results.

HL D&I Halla. has designated the 10th day of each month as “Quality Inspection Day.” On that day, the company, jointly with subcontractors, conducts intensive inspections focusing on construction types with severe or repeated defects to ensure that the most basic principles are strictly observed.

In quality management meetings presided by the president of HL D&I Halla.

the departments concerned discuss quality inspection results conducted over t

he half of the year and the status of defect occurrences. They analyze problems

and come up with counter-measures, reflecting them in on-site quality control.

Outsourcing inspection monitors thoroughly in three steps by break ground / Intermediate / Completed, to check the construction status from design drawing and to prevent construction defect in advance.

HL D&I Halla. conducts construction quality inspections according to progress

rates by sites (initial, 30%, 50%, 70%, 90%) and provides training to on-site

employees over cases of severe defects or repeated defects.

Supervised by the HL Group chairman, the president and executives of HL D&I Halla.

and CEOs of its subcontractors conduct on-site inspections to emphasize

the importance of quality control. (Held four times per year)

In the monthly quality meetings, the departments concerned analyze the causes of defects that occurred during the month and take measures accordingly, while also taking appropriate preventive measures. Moreover, construction quality inspection results are analyzed to strengthen improvement measures and VE (value engineering) activities.

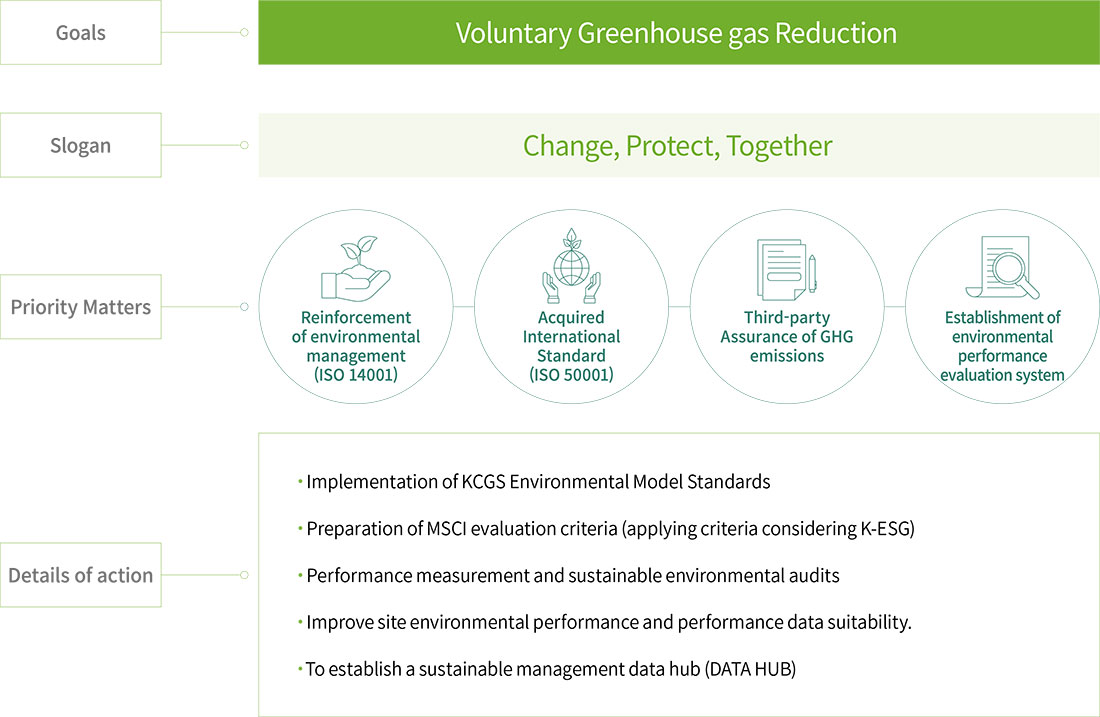

Environmental management We obtained the ISO14001 global environmental management system certification, and established an environmental management manual and environmental directives based on these global standards. All employees and suppliers are in compliance with these manuals and directives in their practice of environmental management. We not only follow domestic environmental laws and regulations and international agreements but also strictly manage construction waste, noise, dust, sewage and harmful materials at sites inside and outside Korea. We also are training experts on the environment to respond to the changing global trends in environmental management.

Construction environment management case contest

Construction environment management case contest

Initial environmental impact assessments aim to seek measures to avoid or reduce harmful environmental impacts by selecting, forecasting and assessing possible impacts on the environment at the initial stage of construction projects. Based on the assessments, Halla E&C establishes and implements environmental management plans and derives key areas of environmental management and manages them, striving to create and maintain a pleasant environment through sound and sustainable development.

HL D&I Halla. has “Environment Day” once per month on which employees cleans up construction sites and their vicinity. Through “One Site, One Green” activities, the company designates rivers, mountains, streets and parks in the vicinity of construction sites and conducts monthly cleaning in collaboration with local governments and local residents, taking the lead in environmental conservation activities.

HL D&I Halla. conducts internal inspections to check the implementation status of ISO 14001 requirements and environment-related areas that may cause environmental pollution such areas as fugitive dust, waste, noise/vibration, water quality and soil and offers guidance and education. By doing so, the company realizes environmental management through ongoing environmental improvements based on its corporate spirit of providing harmonious life between nature and humans.

In order to raise awareness of environmental management and enhance environmental management capabilities, HL D&I Halla. has developed cyber environment education programs and required all employees to receive the training. The company also provides environment education on a frequent basis to all employees on site prior to the commence- ment of work to prevent possible environmental accidents that may occur by work process such as waste and noise/vibration, thereby improving their awareness of abiding by environmental laws and regulations.

We are taking the lead in environmental management practices by conducting continuous environmental education at least once a year for all employees. In order to strengthen the environmental management capabilities of suppliers, we provide separate training for the suppliers' managers and supervisors.

Major Environmental Education Curriculum for 2021

- Environmental Compliance risk management

- Violations of major environmental laws and regulations

- Reporting and taking action on previous inspections

- Enactment and revision of major environmental laws

- Major environmental management guidelines

- Regular seminars for dedicated environmental managers (environmental managers)

To manage air quality at the HL D&I Halla construction site, we have established a fine dust reduction response system and are carrying out scattering dust management activities. Furthermore, we have built an IoT system for real-time fine dust monitoring, and the head office is also building and managing a real-time monitoring system. We have established and are operating a management system that can take immediate action when the reinforced internal management standards are exceeded.

- Distribution of scattering dust management manual for each process

- Establishment of IoT smart safety environment monitoring system

- Real-time monitoring of fine dust concentration data and dissemination of countermeasures

For the safe management of hazardous chemicals, we have established and applied the guidelines for the management of chemical substances to manage all chemical substances. To prevent soil contamination, we are managing the installation standards for pollutant storage facilities. Soil pollution prevention facilities are self-inspected at the workplace on a monthly basis, and regular inspections are conducted semi-annually to check whether there are any contamination activities to prevent the leakage of pollutants. We operate an integrated reporting center to report any contamination activity, and thoroughly manage it.

- Stripping agent storage facility, designated waste storage facility

- Guidelines for chemical management

We have built an IoT system that monitors noise generation in construction sites in real time and measures it in real time to minimize noise. We are reinforcing noise and vibration management by installing noise meters and electronic signboards to keep them below the noise regulation standards (65 dB in residential areas, 70 dB in other areas). We take a preemptive response by inspecting the noise level around the site through a specialized agency.

- IoT-based real-time noise measurement data monitoring

- In the event of an abnormal situation, take countermeasures through notification from the head office

- Adjust material stocking time

- Use of low-noise construction methods and equipment

- Air barrier, air sound barrier, installation

200 |

|||

|---|---|---|---|

150 |

|||

100 |

|||

50 |

|||

0 |

|||

| 매출액량 | 193 |

172 |

220 |

| year | Y19 | Y20 | Y21 |

1,5000 |

|||

|---|---|---|---|

1,0000 |

|||

5000 |

|||

0 |

|||

| 영업이익량 |

2,796 7,238 |

2,423 6,543 |

3,244 8,247 |

| year | Y19 | Y20 | Y21 |

300,000 |

|||

|---|---|---|---|

200,000 |

|||

100,000 |

|||

| 매출액량 |

153,447 153,417 37 |

348,375 348,336 38 |

154,858 154,854 4 |

| 연도 | Y19 | Y20 | Y21 |

150 |

|||

|---|---|---|---|

100 |

|||

50 |

|||

0 |

|||

| 영업이익량 | 75.3 |

93.3 |

148.7 |

| year | Y19 | Y20 | Y21 |

※ In 2020, the increase in waste increased significantly as 160,000 tons

of landfill waste was discovered during construction.